Raw Material: The Manufacturing Process of Dowels

Raw Material: The Manufacturing Process of Dowels

Cincinnati Dowel is a leading supplier of high-quality dowels, offering a wide range of dowel sizes and wood species to meet all your needs.

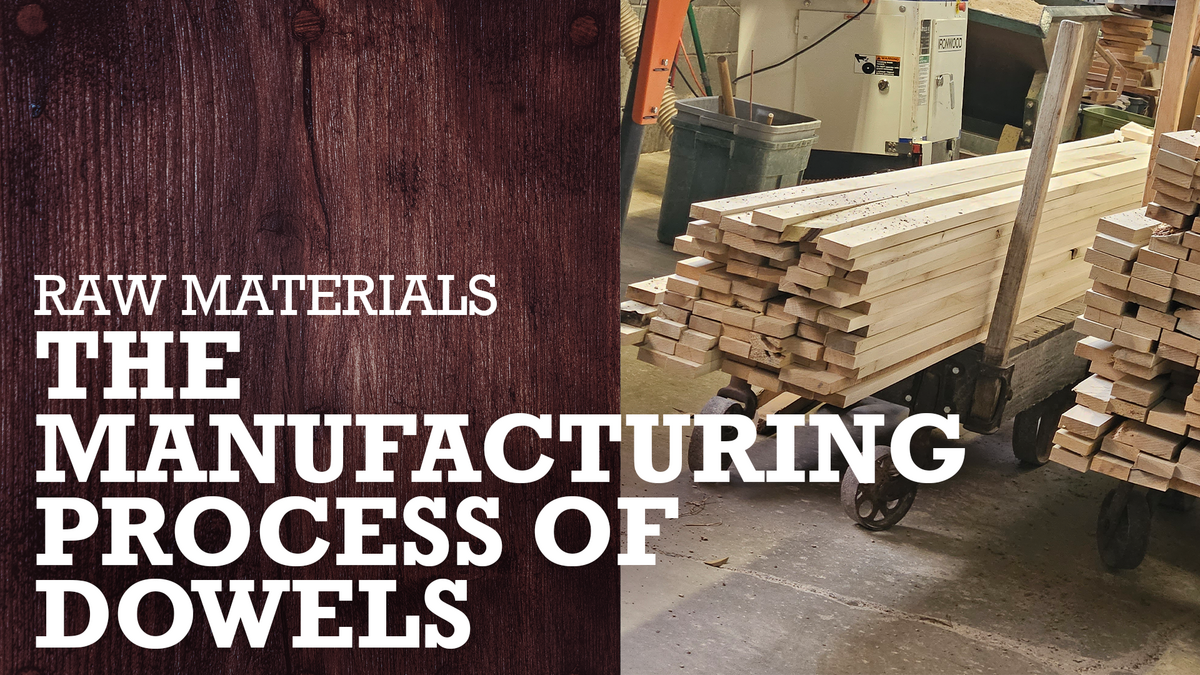

Our manufacturing process starts with carefully selected raw materials, including premium hardwoods. These raw materials are carefully inspected and then milled to the exact specifications required for each dowel size.

In this blog post, we will walk you through our dowel manufacturing process, starting with where our raw materials are sourced and ending with the finished product.

Where Our Dowel Raw Materials Are Sourced

We take pride in sourcing all our raw materials from the Appalachian hardwood region, including Indiana, Ohio, Kentucky, West Virginia, and Pennsylvania. This area is renowned for its high-quality lumber, known for its strength, durability, and beautiful natural grain patterns.

Our lumber is carefully graded based on the number of defects present on the board. We adhere to strict standards, and any material that falls below a certain grade will be returned and not used in our products.

By sourcing our raw materials from the Appalachian hardwood region and upholding strict grading standards, we can consistently deliver quality products for you.

We are committed to maintaining a high standard of excellence, from the sourcing of raw materials to the finished product.

Our commitment to quality and sustainability is reflected in every product of ours.

The Dowel Manufacturing Process

Our wood processing plant follows a systematic process that transforms raw lumber into finished dowels, allowing each piece to meet the required dimensions and quality standards before being used in construction or industrial applications.

The careful consideration of moisture content, sizing, and defects ensures that the resulting wood products can be used.

In our mass production job shop, our wood is stored in outdoor storage facilities such as a dry shed, to protect it from the elements.

When an order comes in, the wood is brought in by a forklift to a planer or rip saw to prepare it for further processing. Next, the wood is taken to a trim saw, where it is cut into the required lengths for the specific product being manufactured.

After being cut, the wood is then directed to a dowel machine or a variety of other product machines, depending on the specific order requirements. The machines are set to run for the order, producing the necessary quantity of dowels or other wood products.

Our manufacturing process is streamlined and efficient, allowing us to fulfill orders on time without compromising the quality of the final product.

By utilizing state-of-the-art machinery and a well-organized process, we can produce wooden dowels and other products to meet the demands of you, the customer.

Inside the Dowel Manufacturing Plant

Inside the wood processing plant, the first step is to make sure that the moisture content of the wood is reduced to 6-10%. This can be achieved through air drying or by using a kiln.

Once the moisture content is at the correct level, the lumber is then ripped to the right width and planed to the right thickness. They are then trimmed on a saw to reach the desired length.

The next step involves running the material through a dowel machine to create dowels, which are cylindrical rods used for a wide range of applications. The dowels are then inspected and sorted for defects to confirm that only high-quality materials move on to the next production stage.

After being sorted, the wood is run through a sander to smooth out any imperfections and create a uniform surface. This step is crucial to verifying that the finished product is free from any rough edges or uneven surfaces.

The wood processing plant follows a systematic process to transform raw lumber into finished products, allowing each piece to meet the required dimensions and quality standards before being used in construction or manufacturing.

Attention to the moisture content, sizing, and defects ensures that the resulting wood products can be used.

When is a Dowel Product Finished?

At our manufacturing facility, we take great care to confirm that each product is of the highest quality before it is considered "finished." To confirm this, each product is individually inspected by hand, looking for imperfections such as knots and bows.

We allow for a 1% deviation over the length of the dowel to account for any slight bowing, and have a diameter tolerance of +/- 0.005”. We also check the length, which has a tolerance of +/- 1/16”

If you want to learn more about the importance of quality control in dowel manufacturing, click here!

In addition to checking knots and bows, our inspectors also look for machine marks and ridges that may affect the functionality and appearance of the dowel. With attention to detail, we guarantee that our finished products meet the standards.

Once a run of dowels is deemed "finished," they are ready to be added to inventory or packaged and shipped out to the customer. We also manufacture dowels that we call “lathe stock” which are used to manufacture other products such as plugs, buttons, spiles, and other turnings, making them versatile and for many different applications.

At any given time, our factory could be producing 50-100 different items a day. These items could include various dowel rods, plugs, pins, as well as a wide variety of other turnings.

By meticulously inspecting each product by hand and adhering to strict standards, we can confidently say that our products are truly "finished" and ready for use.

Manufactured Dowel Products with Cincinnati Dowel

Our manufacturing process at Cincinnati Dowel involves precision and attention to detail.

Using state-of-the-art equipment and skilled craftsmanship, every step in the process is carefully executed to ensure the production of dowels that are consistent in size, shape, and quality.

To browse our full selection of wood dowels and other products, click here!

Happy with the difference Cincinnati Wood products have made for your operations? Leave us a five-star review on Google here!

Want more tips and info on the wood components you use every day? Follow us on Facebook, Instagram, and LinkedIn!